Fill in your specification

You can easily determine the required fuel injector size by entering a few basic details into our calculator. Information about the different headings can be found below the results field.

BASE FUEL PRESSURE AT IDLE (PSI) *

DESIRED HORSEPOWER *

Injector size required

Calculation results, this is the calculated injector size required for your needs. We recommend going with 80-85% duty cycle and never above 90%.

FUEL TYPE |

CC/MIN |

LB/HR |

|---|---|---|

GASOLINE / PETROL |

||

E85 |

* Injector duty cycle (IDC)

Nuke Performance advises a maximum IDC of 85-90% for optimal performance and reliability. Following this recommendation helps prevent performance issues and prolongs the lifespan of both the injectors and the engine.

* BASE fuel pressure at idle

The BASE fuel pressure is measured at idle and the injector calculator counts with a 1:1 rising rate fuel pressure regulator for turbocharged applications. The BASE fuel pressure is set in PSI, here you find an easy-to-use converter from PSI to BAR if needed.

* Estimated horsepower / Crank or Wheel

The power output you aim for directly influences the fuel required to meet your target. Please provide the estimated horsepower and specify whether it would be measured at the crank or the wheels.

Choose the right injectors for your engine, and fuel rail!

When building a high-performance engine, choosing the right injectors is essential for reliability and precision...

We offer a range of injectors (available here) selected for our range of fuel rails, available for more than 30 different engines (available here).

Fuel rails for more than 30 different engines

Injectors from 627cc to 2200cc, from 300 to 2000+ hp

We recommend using high-quality, flow-matched injectors in your fuel system to ensure precise fuel delivery and reliable performance under extreme conditions. Flow-matched injectors provide consistent fuel flow, maximizing power output and efficiency, and is a perfect match to our range of fuel system upgrade parts.

| FIND YOUR INJECTORS HERE |

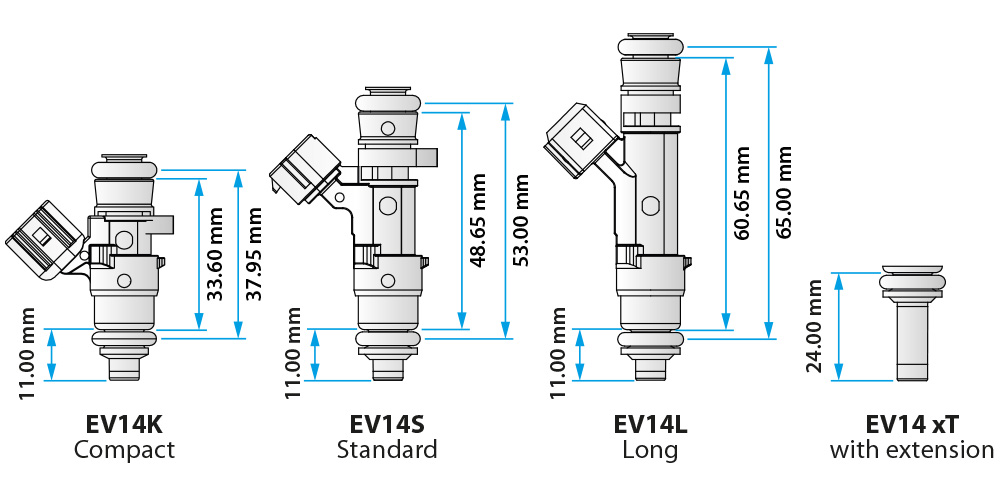

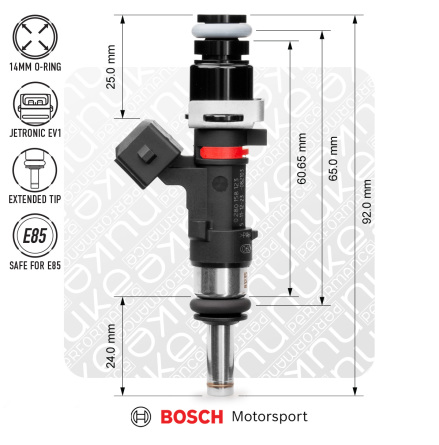

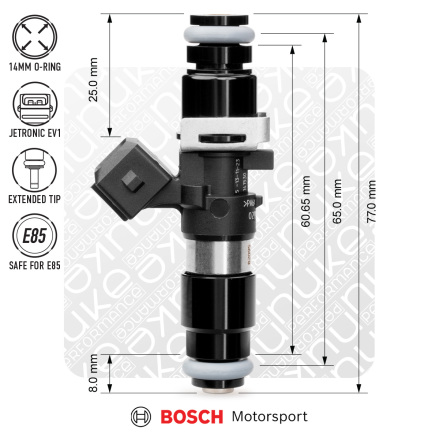

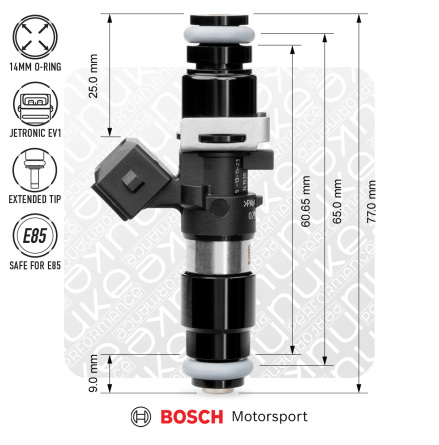

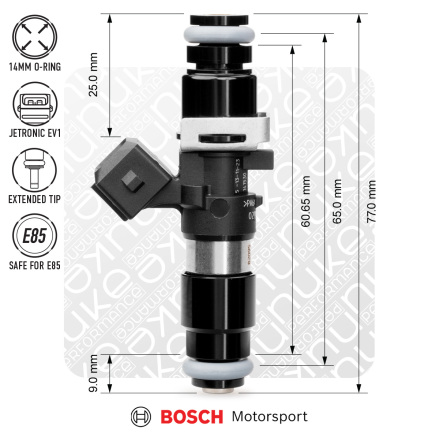

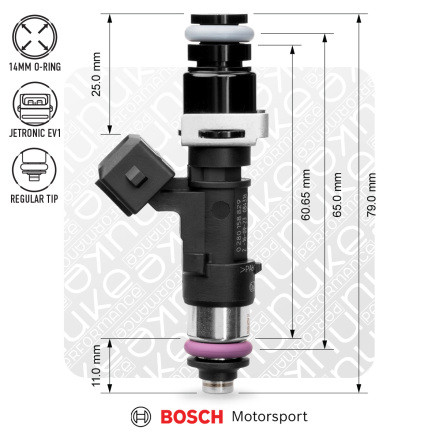

What are the EV14 Injector dimensions?

The popular EV14 injectors come in several lengths to fit various engine applications. All with 14mm O-rings, and the typical lengths include:

EV14K (Compact) 37.95mm

EV14S (Standard) 53mm

EV14L (Long) 65mm *

These lengths ensure compatibility with different fuel rail configurations and intake manifold designs. When selecting EV14 injectors, it’s crucial to choose the correct length to ensure proper fitment and functionality in your specific application.

Long Tip Fuel Injectors (xT)

Some injectors feature a 24mm extension from the lower O-ring. This extension can be inserted into the intake or removed with a lower adapter to achieve the standard 11mm protrusion.

Is there a real need for flow-matching injectors?

Yes, flow-matching injectors is essential for achieving optimal engine performance for high power output engine. Flow-matched injectors ensure that each injector delivers the same amount of fuel, which helps maintain consistent air-fuel ratios across all cylinders.

Matched within a 1% margin ensures maximum performance and durability *

This consistency improves engine efficiency, power output, and overall reliability. Without flow-matched injectors, you may experience uneven fuel distribution, leading to potential engine knock, reduced power, and increased emissions. Therefore, investing in flow-matched injectors is crucial for high-performance applications and ensuring the longevity of your engine.

* We deliver most injectors within a 1% difference, with a top difference of 2% for smaller batch injectors which is still superior to OEM manufacturer injector tolerances.

Injector safety clips, secures the injector to the fuel rail even during an accident.

All Nuke Performance fuel rails (available here) are equipped with unique injector safety clips that secure the injector to the fuel rail in all situations, even during an accident where the fuel rail could rip off the intake as the worst possible ending.

The injector safety clips prevent "fuel rail lift" during racing *

Securing the injector firmly to the fuel rail is crucial to prevent fuel from leaking out of the injector ports during an accident, and to avoid any fuel rail lift or leaks under high fuel pressure in demanding motorsport applications. This precaution helps reduce the risk of a severe fire during racing.

* The key difference between a standard Bosch injector clip and the Nuke Performance safety clips is that Nuke Performance clips are mounted directly into the fuel rail profile using dual M4 bolts, providing enhanced durability and long-term security.

How do I calculate Injector flow, duty cycle, and BSFC?

To calculate injector flow, duty cycle, and BSFC (Brake Specific Fuel Consumption), it´s important to understand how these factors interact in a fuel system and the selection of your injectors. Always ensure a margin of at least 10% to allow for variations when performing these calculations.

BSFC (Brake Specific Fuel Consumption)

BSFC measures how much fuel is consumed per hour to produce one horsepower. The formula is:

Are there any general values for BSFC? Yes, you can use a general value for gasoline engines that can be used if there is no prior data from the engine :

NATURALLY ASPIRATED ENGINE : Gasoline 0.40 - 0.60 / E85 0.55 - 0.75 / Methanol 0.90 - 1.00

FORCED INDUCTION ENGINE : Gasoline 0.60 - 0.70 / E85 0.75 - 0.85 / Methanol 1.20 - 1.50

ENGINE USING NITROUS OXIDE : Gasoline 0.60 - 0.70 / E85 0.75 - 0.85 / Methanol 1.20 - 1.30

Is a lower BSFC value better? Yes, a lower BSFC value means the engine is more fuel-efficient. Maintaining proper fuel delivery is essential for high-performance engines' efficiency and power.

Injector Flow

Injector flow refers to the amount of fuel an injector can deliver, typically measured in pounds per hour (lb/hr) or cubic centimeters per minute (cc/min). Most injectors are identified by their flow rate in cc/min, such as a 630cc injector, which means it can supply 630 cubic centimeters of fuel per minute. To calculate the injector flow rate, you need to know the engine’s horsepower and BSFC (Brake Specific Fuel Consumption). A general formula to estimate injector size is:

This helps ensure proper fuel delivery based on the engine’s power and efficiency requirements. BSFC typically ranges from 0.50 to 0.60 for gasoline engines and recommended duty cycle ranges from 0.80 to 0.90.

IDC (Injector duty cycle)

The injector duty cycle refers to the percentage of time an injector remains open during an engine cycle. We recommend maintaining a maximum duty cycle of 80-85%. Running injectors above 90% capacity is not advised, as it’s important to leave a safety margin. This accounts for factors such as changes in fuel density due to temperature and barometric pressure, as well as the condition and performance of other fuel system components like fuel filters, pumps, and lines.

Keeping this margin ensures consistent and reliable fuel delivery.

Injector operating pressure.

The operating pressure and flow rate of an injector are typically specified by the manufacturer, usually at 3 BAR (43.5 PSI). Increasing the fuel pressure will also increase the flow rate with the same opening time.

For high-performance applications often used in motorsports, it is essential to choose injectors that are made to perform even at the intended operating pressures. Once you've selected the right injector for your power needs, ensure it operates effectively within the expected fuel pressure range.

Ensure the injectors operate within the expected fuel pressure range

Nuke Performance only offers injectors rated as "motorsports injectors" ensuring the highest possible performance. This is especially important when using forced induction and a 1:1 ratio fuel pressure regulator, as many of the standard injectors do not keep an ideal spray pattern when pressure rises cause of added boost.

Does the injector operating pressure impact its spray pattern?

Yes, the injector operating pressure significantly impacts its spray pattern. Different injectors are designed to perform optimally within specific pressure ranges. Operating an injector outside its intended pressure can lead to undesirable flow characteristics and a less effective spray pattern.

For instance, running an injector at too low a pressure can result in poor atomization and incomplete combustion. Conversely, operating at excessively high pressure may cause an uneven spray pattern, potentially leading to issues such as knocking, misfires, and reduced overall engine performance.

In summary, injector operating pressure directly influences the spray pattern, which in turn affects combustion efficiency and engine performance. It is crucial to match the injector design with the operating conditions to achieve optimal results.

Should I use low or high-impedance fuel injectors?

Injector impedance (measured in ohms) controls the electrical current in an injector circuit. The higher the resistance, the more voltage is needed to operate the injector. Injector impedance is measured in ohms.

High-impedance injectors offer several advantages over low-impedance options, making them a popular choice for most applications. They offer a higher compatibility factor, higher efficiency, improved control, reliability, and reduced heat generation, and no need for additional components like injector resistors.

We recommend high-impedance injectors because their faster response times and improved overall control

High-impedance injectors (usually range between 8-16 ohms) are generally considered the more modern choice in today's fuel injection systems. While low-impedance injectors (usually range between 2-4 ohms) were once preferred for their ability to handle larger fuel flows and higher pressures, advancements in technology have led to the development of high-impedance injectors that offer several benefits, making them more popular in recent years.

Historically, peak and hold low-impedance injectors were preferred for large sizes and better fuel pressure control, but today, most aftermarket ECUs support both types, and modern high-impedance injectors offer comparable or even superior performance due to higher voltage handling, faster response times, and improved overall control.

What is the working temperature for an injector?

Fuel injectors typically operate within a temperature range of -40°C to +110°C without significant performance impact. This standard is set by the automotive industry to ensure reliability in various climates, from extreme cold to intense heat.

General working temperature between -40°C and +110°C

The same applies to motorsport injectors, and while there may be slight variations, these temperatures are generally not an issue for most applications. Additionally, modern injectors are designed to be better cooled by the fuel, further enhancing their temperature resilience.

Fuel compatibility of different injectors?

Most injectors can handle both gasoline and alcoholic fuels such as E85 and methanol. However, alcoholic fuels requires more frequent injector maintenance, as the injector needle can become sticky and develop deposits that affect flow and spray pattern.

While modern ECU systems can adjust injector timing to compensate for the fuel mix, the issues with injector flow and spray pattern remain. For this reason, it’s recommended to use a fuel additive that provides lubrication when running ethanol-based fuels and to clean your injectors at least once per season.

Take notice : If using the injector with methanol, flush it with regular fuel after use. Do not leave methanol in the injector for extended periods.

Do injectors need regular servicing?

A brand-new injector typically has a very precise spray pattern that deteriorates over time due to dirt, deposits, and wear.

When using gasoline, these factors are usually minor, but with alcoholic fuels such as E85 (ethanol), the issues become more pronounced. Modern ECU systems with individual cylinder compensation can mask these problems by adjusting for them, but this is only a temporary solution.

Injector servicing is as essential as replacing fuel and oil filters

Injector servicing is as essential as replacing fuel filters, oil filters, and other regular maintenance tasks. Neglecting injector service can lead to uneven engine performance, engine wear, and reduced safety margins as the ECU constantly compensates for one or more cylinders.

In high-performance engines and motorsport applications, regular injector servicing is even more critical. These engines operate at much higher stress levels, pushing both components and fuel systems to their limits. Any decline in injector performance, such as a disrupted spray pattern or clogged injector, can result in significant power loss, reduced efficiency, and even engine damage.

Motorsports engines demand precise fuel delivery to maintain peak performance. Additionally, with higher fuel flow rates and more extreme operating conditions, the margin for error is much smaller, making proper injector maintenance essential to prevent costly failures and ensure optimal performance on the track.

Products mentioned on this page

-

€ 87,81

-

€ 97,69

-

€ 103,63

-

€ 113,00

-

€ 155,25

-

€ 118,25